| Dispenser |

| Product |

2-Component Type Automated Dispenser |

|

| Model |

TD2-S1 |

| Overview |

This is a machine that measures, mixes and dispenses the 2 types of liquid resins such as epoxy, urethane, and silicone quantitatively. The measurement is based on 1 motor and 2 gear pump system. |

| Features |

Because the rotation ratio is fixed mechanically, it ensures the stable compounding ratio even against changes of material viscosity and pressure changes caused by hardening of the mixing unit, Also, because it can change dispensing flow rate (g/second) without concerning deviation of compounding ratio, so it can easily to handle various kinds of works.

About mixing unit, we have various types; static, power mixer, disposal non-wash, etc.

We will select the best one according to your requests and conditions of use.

|

| Specification |

[ Standard Specification ]

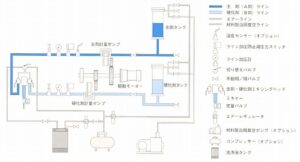

・Compatible with various materials; from small to large amount, even contained filler.

・Built in autocycle dispensing (automatic intermittent dispensing); this prevents hardening of the mixing head. It’s effective during lunch break or waiting time for work.

・Equipped with temperature control system from material tank to mixing head; this enables dispensing with a stable material viscosity.

・Measurement system has 1 motor 2 gear pumps; this provides a stable compounding ratio.

Also by changing rotation speed of gear pump drive motor, it can vary the dispensing flow rate without changing compounding ratio.

・The compounding ratio is set by combining the pump capacity (cc/revolution) and the number of teeth of shaft gear, therefore, there is no deviation in the compounding ratio caused by viscosity changes due to temperature or resistance fluctuations in pipes.

Standard machine size (width) 100 × (depth) 700 × (height) 745mm

Compounding ratio 100:100~100:1

Dispensing flow rate 0.01cc/sec~30cc/sec

Dispensing accuracy within ±3%

Compatible viscosity 200,000cps Max

Dispensing timer 0.1sec~99.9sec

Cycle of automatic dispense Stop time 30sec Dispense time 6sec

Material tank 4l pressure-resistance clear glass tank ×2

Wash tank 10l stainless steel tank×1

Mixer :static mixer (disposal type)

Dispensing operation:Foot switch with dispensing signal outlet

Power/Air source single-phase 100V 250W/ more than 4kgf/cm2

Option large size tank 20l~200l material vacuum defoaming system power mixer(forced stirring type)

|

| |

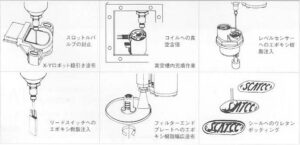

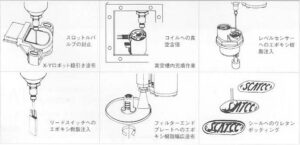

Practical example

|

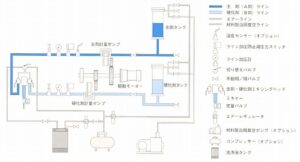

System diagram

|

| |

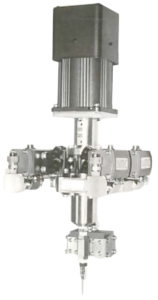

< Measuring pump >

Rotary gear pump

[ Features ]

Excellent wear resistance and long lifetime because it uses special stainless steel.

No leakage because it uses precision gear pump made for dispenser.

No pulsating because it uses rotary type.

|

| |

< Gear pump >

We have 6 sizes of gear pumps according to the dispensing amount.

2.297cc/revolution

0.584cc/revolution

1.168cc/revolution

2.920cc/revolution

5.00cc/revolution

7.600cc/revolution

|

| |

< Mixing system >

It can mix reliably even materials with different viscosity because material channel is divided.

[ Features ]

No troubles because there are no movable parts.

No need disassembly washing. It can be washed by washing system equipped in the machine.

Maintenance free because it uses disposal type (daily exchange type).

Quick and at the low cost restoration to work just exchange the mixing part, even though it hardens due to work mistake.

It adopts divided into two type static mixier.

Available to add the element depend on the mixing state, so you can obtain appropriate mixing effect.

No troubles because there are no movable parts.

|

| |

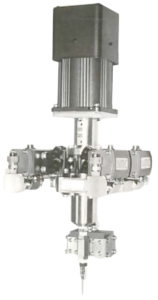

< Power mixer >

It adopts forced stirring type mixer.

[ Standard Specification ] [ Standard Specification ]

Mixer motor Continuous speed variation

Rotation speed 3,600rpm MAX(60Hz)

Chamber capacity 3~10cc

Dispensing flow rate 0.05~15cc/sec

Dispense/wash switching valve Automatic valve or 3-way manual switching valve

Wash Automatic valve or 3-way manual switching valve(air/solvent switching)

Quantitative valve Actuator valve

Weight 6kg

Option Temperature control jacket

|

| |

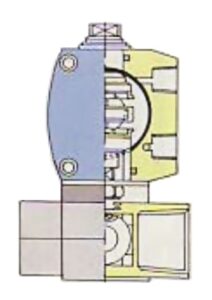

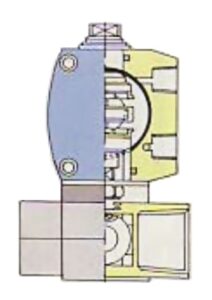

< Quantitative dispense valve >

This is a valve to prevent liquid drop from the nozzle.

[ Actuator valve ]

This is a system in which a two-way ball valve is driven by a rotary air actuator. Since the air drive part and the material flow part are completely separated, the material doesn’t enter in the air driven part.

|

| |

|

All of our machines, we have been manufacturing according to customer requests.

There are various achievements from small devices for research to mass production devices, if you have any question, please contact us.